| Broken Flybar Mount |

| Broken Lower Rotor Pivot |

| Tail Drift or "My heli wont stop spinning" |

| Shorter Flight time |

| "Toilet Bowl" Motion |

| Vibration After A Crash |

| DIY folding blades |

| Throttle Stick Mod - Make your heli hover BETTER |

Inner Shaft with Hub - breaks just below the flybar

The upper rotor hub is designed in such a way that the plastic is VERY THIN where the hub narrows above the blade mounts and below the flybar mount. The inside of the hub is hollow all the way through, so the long, heavy flybar is mounted on a thin tube at that point. If you have a clean break, you can glue it back together with CA or Epoxy. Once it's broken and glued it breaks much more easily afterwards. Be careful with a glued hub.

To fix it simply glue the pieces together. If you cant fit it together easily (like if you somehow get a perfectly flat break) Make sure you glue it so that the flybar will be closest to the LEADING edges of the blades... The easiest way to reinforce the hub is to wrap it in thread and cover the thread with epoxy or CA.

Here is the finished upper hub. Wind the thread tightly around the hub and then coat with CA or epoxy. I just used regular super glue.

Back to TOP

Lower Rotor Head-Pins shear off

You might not even know this part is broken, because the BCX still flies ok if just one breaks. One of the two plastic pins that form the lower rotor pivots can break in a crash. so this is something you may want to check now and then.

Note: If you've broken the upper rotor hub, check the lower rotor pivots, because you may have broken one, too. If the second one is cracked and breaks in flight, it could get nasty.

Fix #1. Use a #38 drill bit because it most closely matches the diameter of the pins. (.100")

Remove the lower rotor head piece from the heli and drill the holes with the #38 bit (if possible use a drill press to get the holes nice and perpendicular to the hub surface.) After drilling the holes use a Dremel tool with a cutoff disk to cut the pins (which you cut from the drill bits shank) to the proper length. Sand the edges a bit and CA them in place.

Fix #2. Remove the lower rotor head piece from the heli and drill a 5/64" hole through the part were the blade holder pins used to be. Cut 2 pieces of 5/64" (.080) music wire approximately 3/8" long. You can cut the pieces off a broken inner shaft instead of music wire if you have one. Slide the lower rotor head back on and insert the wire into the holes. Use a small drop of thin CA at the base of the wire. Remove from outer shaft and let dry before re-installing.

Fix #3. Posted By kemper.

I repaired my lower pin with carbon rod. The size is .097 I think.

1. Shear both pins off as cleanly as possible.

2. Use a brand new xacto knife to center a hole where to drill out the area where the plastic pin had been.

3. Drill a hole a little bit smaller than the size of the carbon rod.

4. Ream the hole out with the drill until the carbon rod fit into one hole, through the center, and out the hole on the other side.

5. Cut the rod on one side so that now both side stuck out the correct length.

6. Apply a decent amount of CA to the outside, and a pretty liberal amount to the inside, so that the glue is on both sides of the pins.

7. Let everything dry overnight.

8. Because the carbon rod goes through the center of the assembly where the inner shaft needs to go, simply drilled out the center to remove the carbon rod and excess glue.

Back to TOP

Tail drift, why wont my heli stop spinning even with full left/right trim?

Some Blade CX's seem to have a problem where no matter how you adjust the pot on the gyro, you have to constantly adjust the trim on the transmitter, and by about halfway through the flight you have run out of trim and have to hold the rudder over to keep from spinning.

Fix #1. If you dont want to do any actual modifications to your BCX, the best way to deal with the tail drift issue is to "reset" the gyro once it starts to drift. To do that all you have to do is unplug the battery and plug it back in.

Fix #2. If you are willing to modify/cut your heli, then this is a better solution. What you need to do is cut holes in the canopy and the case of the 4-in-1.

One key to effective cooling is the proportion of the OUT versus the IN. The OUT airflow should be 2-3 times that of the IN airflow. This is what creates good flow properties. IF you do not get the proportions right the air gets captured doesn't do as good a job evacuating the heat. It will still help, just not as much as if you get the proportions right. First thing to do is cut the canopy. One easy way to do this and make it look nice is with a dremal tool and sanding bit, cut an inital hole with a razor, then use the dremel to get the size/shape you like.

You can see here on Rickgodes' heli that he has cut a hole in the canopy AND removed the case from the 4-in-1.

You can either remove the case from the 4-in-1 as above, or just cut/drill some holes in the case.

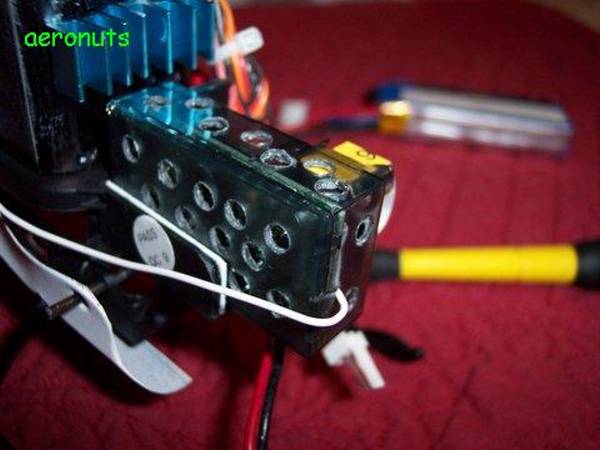

You can see aeronuts drilled holes in his 4-in-1 cut his canopy

BEFORE you drill holes in the 4-in-1 case you want to remove the 4-in-1 from the case, for obvious reasons. First mark then remove all wires from the 4-in-1 unit. Remove the unit from its base on the Blade, its stuck on with double sided tape. Remove the two small screws from the end of the case. Tilt the top up from the screw end and remove. Now there is a small piece of double sided tape holding the circuit board inside the case, so very carefully pry up one end of the circuit board and then work yourself around the case till it pop's loose. It's really easier then this sounds.

Back to TOP

Shorter Flight time

You notice that you are getting much shorter than normal flight time than you used to.

Heli hovers in a circle but facing in one direction.Also Known as the "toilet Bowel effect"

Here is something you might notice after a crash. You take off and your heli hovers in a circle but facing in one direction. (as if it were being flushed down a giant toilet) Generally the "circle" is about 2-3 ft wide and it takes it about 1.5-2 seconds to make it's circuit.

Back to TOP

Protect your 4-in-1 by allowing the blades to fold when they hit something

This Mod was originaly posted on RC groups by 3VW and what follows is a cut and paste of his post.

I took a couple of my broken blades and made blade holders. I cut their shape on a band saw and then drilled and tapped the holes (2/56 thread). I also took an exacto knife and shaved the vertical support off so the surface would be flat.

I next took both the upper and lower blades (before cutting their ends off) and measure out (3/16”) the center points for drilling my holes. I did this step first, to maintain the symmetry and balance of the blades before I went ahead and cut the ends off.

I then evenly cut all (4) ends of the blades off and simply took a file and rounded the ends.

I used (4) 2-56 x 3/8” brass screws with washers to hold the blades on. They are screwed into the threaded blade holders and then additionally tighten (on the back side of the holders) with (4) 2-56 brass nuts and washers.

Back to TOP

Smooth the throttle.

The throttle stick on the Blade CX has built in "ratcheting' which makes it impossible to get the throttle set right for a stable hover A simple and useful modification is to remove the notches from the throttle stick on the transmitter. This will give a much improved hover and vastly smoother take offs and landings.

There are four screws holding the back of the transmitter on, remove these and unscrew the antenna.

Once the back is separated you can unplug the power lead from the circuit board for ease of access.

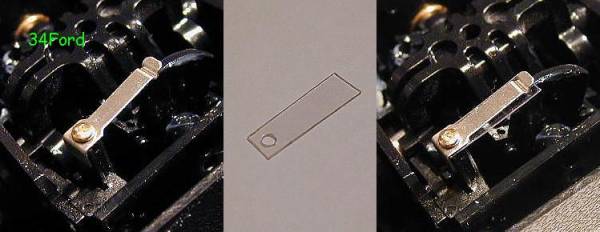

On the throttle stick you will see a small metal strip held in with a screw remove the screw and metal strip.

From here there are a few things you can do.

1. Sand the plastic part down so its smooth. It has to be REALLY smooth, if you dont sand it enough you will still be able to feel the notches, so once you think you have got it smooth, sand it a little more...

2. Put a piece of fuel tubing over the metal strip.

3. Put a piece of plastic between the metal strip and plastic, see below.

4. There is a little hump formed into the strip that makes the notches. You can flatten the hump with a small hammer on a hard surface and then reinstall the strip and screw.

5.Flip the metal piece over. You'll no longer feel the notches, and the resistance can be adjusted by bending the steel a bit.

Back to TOP

After a crash, the heli will often start vibrate as you spool it up

So you crashed, and now your heli vibrates badly as you spool up the blades. The vibration will become less noticeable once you are airborne, but trust me, its still there, and its making your heli fly worse and draining your battery faster.

there are no adjustments for lower blade tracking. If they aren't tracking right it might be one of several things. a. The lower rotor head has a cracked or broken blade support (see Broken Lower Rotor Pivot)

b. Take out the screws holding the blades and make sure the plastic blades fit together tight (if they don't quite seat correctly, it can cause problems with upper and lower blades). Reset screws.

c. Pop the linkages loose from the blades and reverse them, i.e. left goes right, right goes left (I know it sounds crazy, but it has worked for some people).

d. Replace the blades one at a time. Change one and fly, if it doesn't help replace another and fly. Sometimes after a mishap they appear fine but might have a vibration in them. Slightly bent plastic??? I don't know, but try it.

Back to TOP

This page was made possible by all the great people from RC Groups!

Special thanks to....

Rodono

3vw

Vario 3

rickgode

34Ford

Roadkill

LRHann

Absolutt

Aeronuts

Provided by 3vw @ RCGroups

Provided by 3vw @ RCGroups

provided by Aeronuts @ RCGroups

provided by Aeronuts @ RCGroups

By 3vw @ RCGrouops

By 3vw @ RCGrouops

Built by copperclad @ RCGroups

Built by copperclad @ RCGroups